About Sigma Melleable

Welcome to Sigma, where craftsmanship meets innovation in the world of metal casting. With a rich history and a commitment to excellence, we are a leading foundry dedicated to delivering top-quality metal products that meet the diverse needs of our clients.

35 Years Of Experience

35 Years of Innovative Solutions for Our Valued Clients.

Quality Assurance

Rigorous Selection and Control for Excellence in Every Product.

Experience

Sigma Melleable Best Foundry in India

Sigma Deliverables

Value For

Money

Shorter Development

Cycle

Delivery - On Time,

Every Time

Process

Excellence

Customer

Focus

Sustainability For

A Better Tomorrow

Professional & Dedicated

Team

Strong Technical

Capabilities

Sigma Melleable Best Foundry in India

Our Infrastructure

Sand Plant

Our Sand Plant is equipped with sand multi-controller (SMC) which regulates and monitors the process in a sand mixture.

Moulding Facility

SINTO JAPAN FBO N – III Horizontal Parting Flaskless Molding Machine in which all molding sequences are carried out at a single work station.

ARPA 450 & 900

Simultaneous Jolt Squeeze Moulding Machine High frequency, low amplitude jolting with high dynamic squeeze force for uniform and rigid moulds.

Sand Core Shop

MAKE WELL Fully automatic cold shooter (25 Lt, 15 Lt, 10 Lt, 5 Lt Capacity) with blowing time varying between 30 Second and 2 minutes with one ton per hour sand mixture.

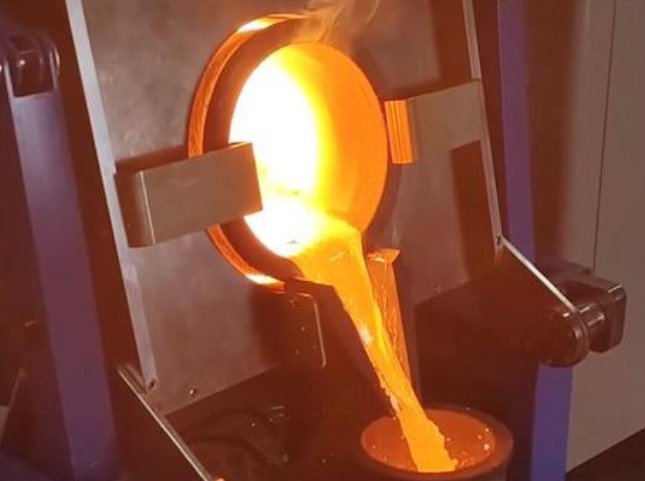

Melting

30 MT Per Day Melting Capacity. Dual track induction furnace 500 kg/hr – 2 Nos. & 750 kg/hr – 2 Nos. Tight chemistry control with complete traceability Customized software and control for efficient energy management.

Machine Shop

Modern & advance machine shop with setup of CNC, VMC and VTL machines, operating in a true Lean and energy efficient environment.

Wide Range of Casting parts

As a major supplier to OEM & Tier-I Suppliers, we manufacture machined castings for a wide range of applications

Motors

We are one of the established names of the industry engaged in manufacturing and supplying electric motor casting parts .

Pumps

Our pump parts are manufactured from optimum quality materials that ensure toughness and wear resistant.

Gear Box

Pipe Fitting

Valve Industries

Air Compressor

Three Wheeler

Specializing in three-wheeler parts casting, Sigma Melleable utilizes metallurgical processes to ensure the durability and precision of components.

Tractor & Farm Equipment

Sigma Melleable specializes in casting components for agricultural machinery, employing metallurgical processes to ensure the durability and performance of the produced parts.

Earth Moving

Sigma Melleable specializes in casting robust components for heavy-duty equipment used in construction and excavation projects.

GET TO KNOW SIGMA MELLEABLE BEST FOUNDRY IN INDIA

DO YOU HAVE ANY QUESTION? FEEL FREE TO CONTACT US.

Performance Metrics Unleashed

CERTIFICATION

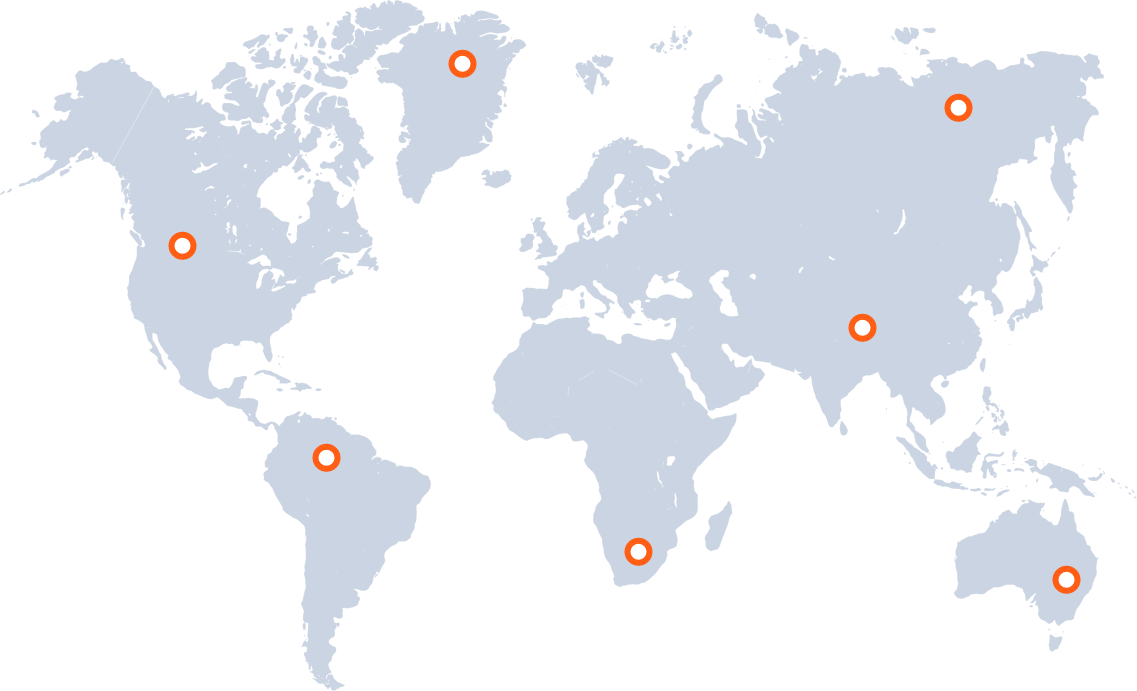

We're

Any Where In The

World

Production Capabilities

Quality & Eco-focused Production

Associate Network

20+ Partners - United for Customer Excellence

Global Presence

Spanning the Globe with Excellence and Innovation

Worldwide Operations

68+ Countries - Local Expertise on a Global Scale

Concise answers to commonly asked questions

Sand casting emerges as a competitive choice for manufacturing larger parts with complex shapes or diverse material requirements. Its straightforward mold manufacturing process lends itself well to small batch production and rapid prototyping. Furthermore, the adaptability of sand casting allows for its application across a spectrum of metal alloys, enhancing its versatility as a casting method.

Addressing internal voids and pores is a common challenge in sand casting. To mitigate these issues, steps are typically taken, including enhancing the venting performance of the sand mold, regulating the temperature and fluidity of the liquid metal, and employing suitable pouring techniques. Quality control measures involve non-destructive testing of castings to identify potential internal defects.

The sand casting process is widely recognized as an environmentally friendly casting method, and Sigma exemplifies this commitment by utilizing renewable sand material for molds, advocating for multiple reuses. Additionally, the active involvement in recycling and reprocessing of discarded sand molds reflects Sigma’s dedication to sustainability. However, environmental considerations persist for sand casting manufacturers, particularly in waste and wastewater treatment. Sigma remains steadfast in its commitment to minimizing environmental impact through continuous initiatives.

Sand casting foundries are versatile and can cast a wide range of materials. Some common materials that can be cast in sand casting foundries include:

- Gray Iron: A widely used material known for its strength and durability.

- Ductile Iron (Nodular Iron): Offers high strength and ductility, making it suitable for various applications.

- Steel: Sand casting can accommodate different types of steel, providing flexibility for diverse applications.

- Aluminum: Widely cast in sand foundries due to its lightweight nature and corrosion resistance.

- Brass: A copper-zinc alloy known for its corrosion resistance and attractive appearance.

- Bronze: An alloy of copper and tin, chosen for its strength, corrosion resistance, and aesthetic qualities.

- Copper: Often used in sand casting for its excellent thermal and electrical conductivity.

- Magnesium: Lightweight and with a good strength-to-weight ratio, used in specific applications.

It’s important to note that the suitability of a material for sand casting depends on factors such as the casting process, the intricacy of the part, and the desired properties of the final product. Consultation with the specific foundry is crucial to determine the best material for a particular application.

Get In Touch

Phone Number

+91 99093 80133

info@sigmamelleable.com

Office Location

Sigma Melleable Private Limited, Plot No-2, Survey No: 151, Tal. Kotda Sangani, Padavala, Dist-Rajkot, Rajkot -360030 Gujarat, India