QUALITY ASSURANCE

- Home

- Quality Assurance

Quality

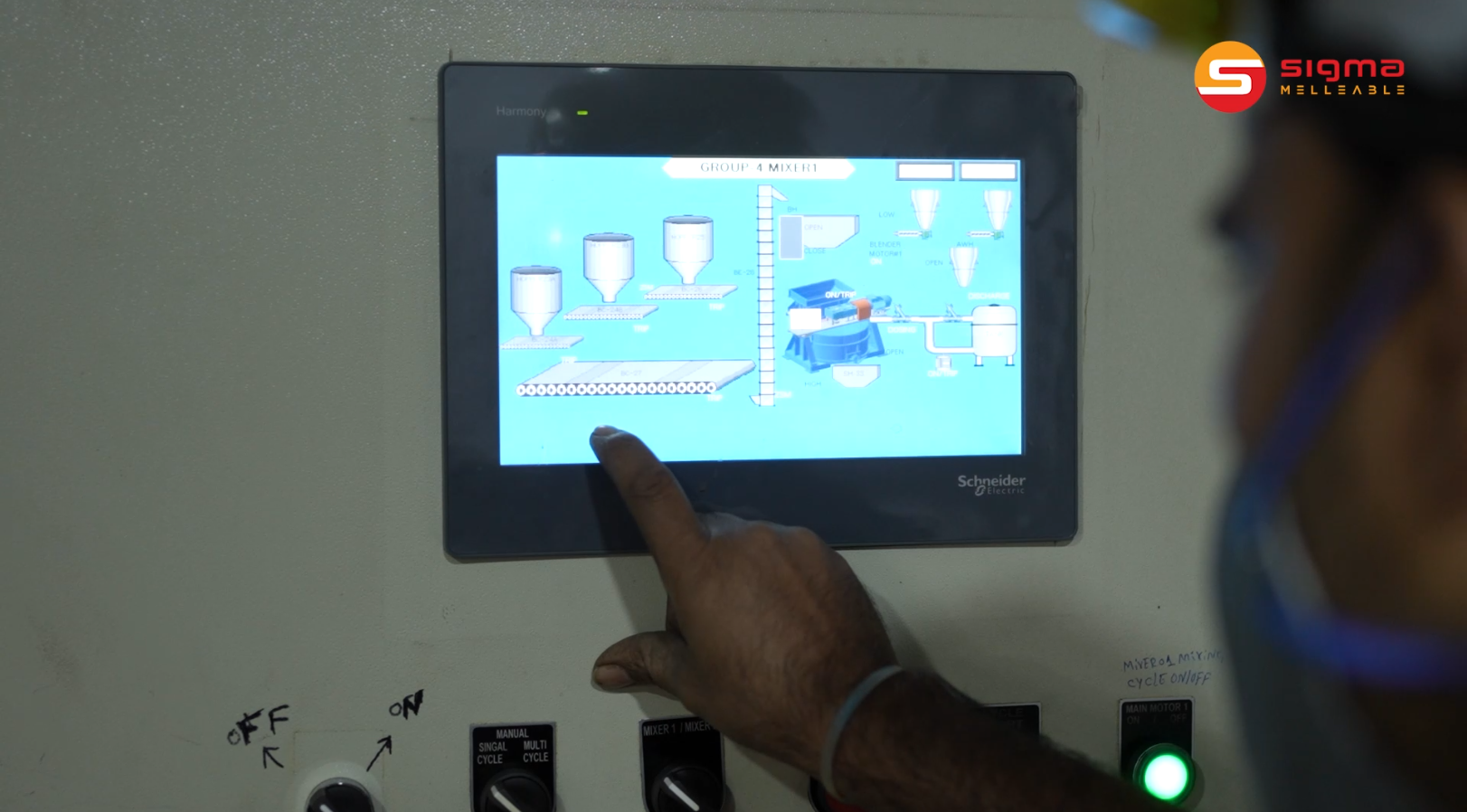

At Sigma Melleable, we pursue quality in everything we do. We employ a wide range of quality initiatives, implementing an effective quality management system, 8D, 5 Why, and kaizen problem-solving. Through these efforts, we are well on our way towards creating high-quality products.

In our Advance Product Quality Planning(APQP), we have successfully minimized variability and evaluated quality in our manufacturing process. This ensures we deliver products that delight our customers and keep them coming back for more. With 35 years of doing business, our customers can be assured that quality will never be compromised.

Testing Facilities

Metallurgical Testing

- Microscope with image analyser with built in camera

- Brinell Hardness Tester

- Rockwell Hardness tester

- Universal Testing machine

- Impact testing machine

Sand Testing

- Mould Hardness testing

- Universal sand testing machine

- Permissibility meter

- Sieve shaker

- Moisture tester

- Wet tensile tester

Chemical Testing

- Specto-meter with 19 elements testing

- Carbon Silicon Analyser ( CE Meter) with recorder

- Modularity testing (Ductile Iron parts)

Dimensional Assurance

- CMM- Zeiss ( 1200x1000x600 mm)

- 2-D height Gauge

- Surface roughness tester

- Surface Plate

- Marposs Gauge for bore measurement

- Air Gauge unit with SPC futures

Non Destructive Testing

- Magnetic particle done by approved agency

- Dye penetrant testing

- Radiographic testing is done by approved agency

- Ultrasonic Flow detector testing is done by approved agency